SM2258XT_HY16_PKGQ0630A_MPQ0629A_FWQ0630A 是针对慧荣 SM2258XT 主控固态硬盘的量产开卡工具包,包含固件(FWQ0630A)、量产工具(MPQ0629A)和配置文件(PKGQ0630A),适用于特定闪存颗粒(如海力士 16nm TLC)的硬盘修复。以下是关键信息及操作要点: 工具包组成- PKGQ0630A:配置文件,定义量产参数,如闪存类型、容量、序列号等。

- MPQ0629A:量产工具,用于扫描硬盘、配置参数并执行开卡操作。

- FWQ0630A:固件文件,用于更新或修复主控固件,解决硬盘故障。

适用场景- 硬盘故障:硬盘无法识别、无法分区、读写异常等。

- 固件损坏:主控固件异常导致硬盘无法正常工作。

- 数据恢复前准备:通过开卡修复硬盘结构,为后续数据恢复创造条件。

操作步骤- 准备工作:

- 硬件:拆解硬盘,确认主控型号为 SM2258XT;使用 SATA 转 USB 转接板或移动硬盘盒连接硬盘;准备短接工具(如镊子)。

- 软件:下载并解压工具包;确保电脑为 Windows 系统(建议 Win7/10),关闭杀毒软件。

- 进入工程模式:

- 断开硬盘电源,短接 ROM 跳线(通常位于 PCB 板上标注为 JP1 或 ROM 的两个触点)。

- 保持短接,将硬盘通过转接板连接到电脑 USB 接口。

- 打开磁盘管理,确认出现 1GB 未分配空间(表示进入工程模式成功)。

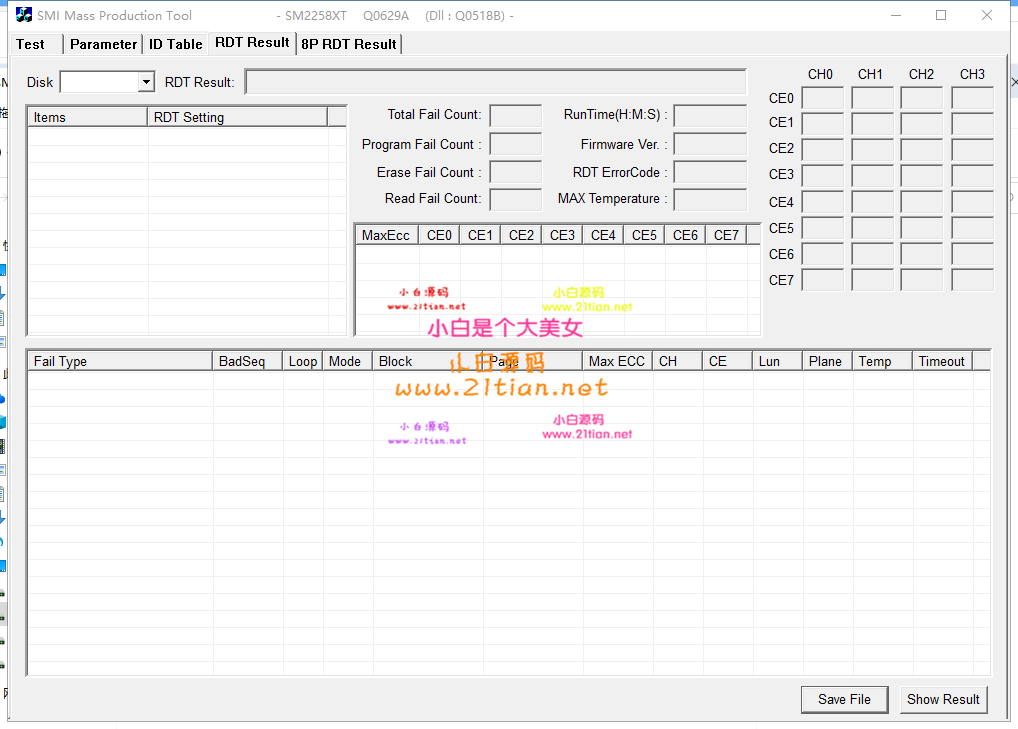

- 量产开卡:

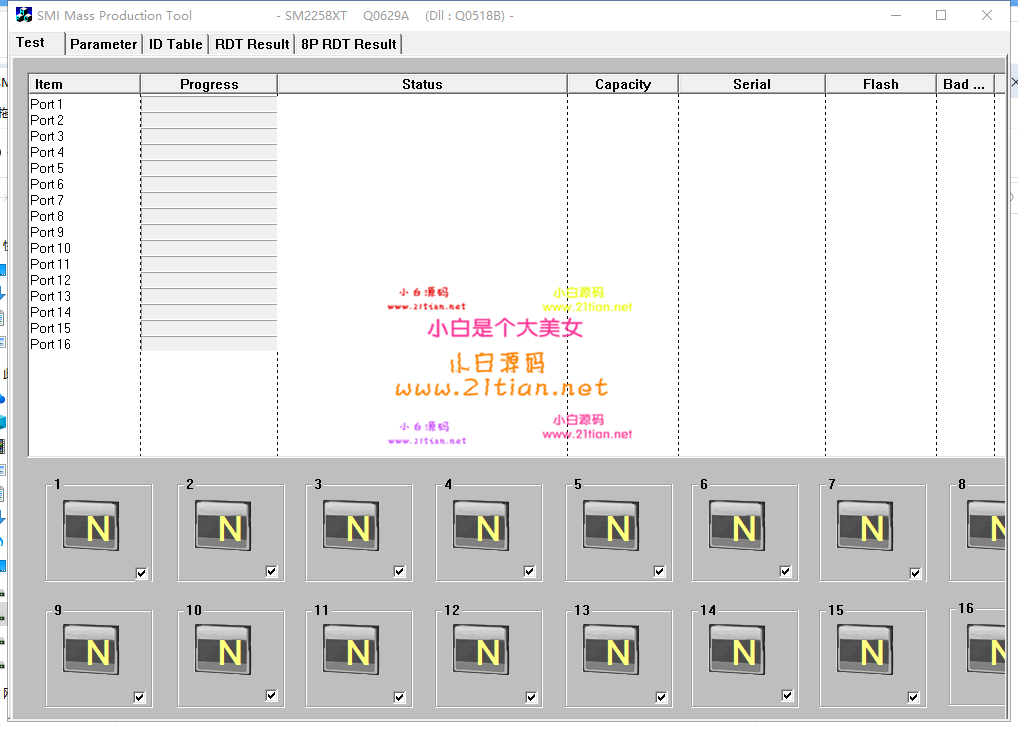

- 运行 MPQ0629A.exe(以管理员身份),点击 Scan Drive 扫描硬盘。

- 进入 Parameter 选项卡,点击 Edit Config,输入密码(通常为两个空格)。

- 配置参数:

- Flash Select:选择 Auto 自动识别闪存颗粒,或手动选择对应型号。

- Disk Capacity:设置硬盘容量(如 120GB、240GB)。

- 其他参数(如序列号、厂商信息)可自定义或保持默认。

- 保存配置后,返回主界面点击 Start 开始量产。

- 等待进度完成,出现 PASS 标识表示开卡成功。

- 后续操作:

- 关闭量产工具,断开硬盘电源,重新连接电脑。

- 使用磁盘管理或 DiskGenius 对硬盘进行分区、格式化。

- 测试硬盘读写功能,确认修复成功。

注意事项- 数据备份:开卡会清空硬盘所有数据,操作前需确认无重要数据或已备份。

- 兼容性:确保工具包与硬盘闪存颗粒匹配,如 HY16 表示海力士 16nm TLC 颗粒。

- 风险:自行开卡可能导致官方保修失效,建议过保硬盘操作。

- 错误处理:

- 若出现 Not MPIS Mode 错误,检查短接方式或更换转接板。

- 若无法识别硬盘,尝试更换 USB 接口或量产工具版本。

|